HOW WE SUPPORTED AGI WESTFIELD’S ENERGY EFFICIENCY UPGRADES

Agriculture is an essential driver of Manitoba’s economy. When businesses in the agricultural industry flourish, so does our province along with the people who live and work here. We recognize this, and we’re committed to helping these businesses succeed by making energy efficiency accessible and more affordable.

Since becoming operational in 2020, we’ve helped numerous agricultural operations make energy-saving upgrades through financial incentives and technical assistance. And the types of businesses we’ve supported are wide-ranging, from small-scale farms to large corporate operations. With a wide range of offers and a collaborative approach to working with customers, Manitobans involved in agriculture have been empowered to make energy efficiency improvements in their operations, enjoying lower energy bills and enhance their production processes.

While Efficiency Manitoba often works with farmers in the agricultural industry, we also work with the businesses that support these farmers. Keep reading to find out how we helped AGI Westfield discover and implement new strategies to save energy and money in their manufacturing facility.

ABOUT AGI WESTFIELD

AGI supplies a wide range of products related to grain storage and movement around farms, commercial grain handling facilities, as well as fuel storage. These include bins, conveyors, augers, grain legs, fuel tanks, and more. By furthering agricultural storage, handling, and processing solutions, AGI is working to strengthen the global food supply chain.

FINDING ENERGY-SAVING OPPORTUNITIES THROUGH A BENCHMARK STUDY

When AGI was looking at improving the energy efficiency at their Rosenort facility, they knew to reach out to Efficiency Manitoba first. We understand the unique needs of industrial facilities and farm operations, making our tailored offers particularly valuable for companies like AGI.

“When I first reviewed our compressed air system, I could see there was a significant opportunity for our Rosenort facility, so it was my mission to spearhead this project,” shared James Kehler, AGI Westfield’s Facility Manager. “The old compressed air system was inefficient and maintenance intensive.” Having completed a variety of energy related projects before, James reached out to us for support with a benchmark study of their facility’s compressed air system.

The project continued with AGI selecting a pre-qualified contractor to visit their facility and assess their current system. We analyzed the data provided by the contractor and developed a comprehensive report that included detailed information about the facility’s compressed air system and opportunities for energy efficiency improvements. We determined AGI would benefit from a compressed air upgrade, and we could support with financial incentives towards the cost of the upgrade through our Custom Energy Solutions Program.

SAVING ON UPGRADES THROUGH OUR CUSTOM ENERGY SOLUTIONS PROGRAM

Our Custom Energy Solutions Program offers incentives to industrial, large commercial, and agricultural customers who take on energy-saving projects. Participants can receive a performance-based incentive of $0.25/kWh and/or $0.30/m3 of annual energy saved. The more energy a project saves, the higher the incentive.

This program lives up to its name, as the projects are truly customized to each unique facility and to each project. Upgrades may include industrial refrigeration, pumps, fans, variable speed drives, steam, ventilation — and, of course, compressed air. We consider all projects that reduce electricity or natural gas consumption.

When AGI Westfield saw the savings potential of a compressed air upgrade coupled with the incentive dollars we offered, they knew it was a project well worth the investment. With our financial assistance, they were able to purchase and install a new, higher efficiency 125-horsepower variable speed drive (VSD) air compressor and a new 100-horsepower VSD air compressor. Both compressors are equipped with integral cycling dryers. The project included a new building for the installation of the equipment, which also incorporates heat recovery ventilation to direct waste heat out of the compressor room. In the winter, this heated air is directed inside to help offset space heating, and in the summer, it’s discharged to the outside.

“There were a ton of benefits to this project. The annual energy savings are a huge advantage of course, especially considering how energy-intensive compressed air systems are. But we’re also seeing major operating and reliability benefits, so our overall operations are even more efficient and productive.”

James Kehler

Facility Manager, AGI Westfield

THE SAVINGS

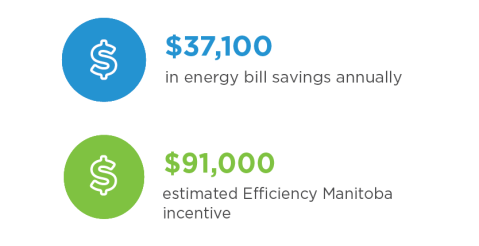

AGI Westfield’s compressed air upgrade was a significant investment, but it yielded even more significant benefits. The verified energy savings will result in a reduction in their energy bills of over $37,100 annually! Since the costs of maintaining their new energy-efficient system are lower and its reliability is greatly improved, they’ll also see annual maintenance savings.

Further contributing to the financial benefits of this upgrade was the $91,000 incentive we provided AGI for choosing an energy-efficient compressed air option. This brings the project payback period to roughly three years.

“Working with Efficiency Manitoba has been a great experience,” said James. “Not only did their incentive substantially reduce the cost of the upgrade, but they were supportive and informative throughout the entire process. Combining the benefits of energy savings with productivity, reliability, and the incentive — that’s a successful project.”

YOU CAN COME SAVE WITH US, TOO

With a variety of offers including their signature Custom Energy Solutions Program, we’re ready to help businesses and facilities across the agricultural sector improve their energy efficiency. We’ll identify energy-saving opportunities suitable for your operations and provide assistance along the way, from calculating your project’s energy savings and incentives to completing application forms. Our team of experts will help you discover the best options to save you the most energy and money.

Supporting innovative approaches to energy efficiency is a core component of our work. If you have a project in mind and need a better understanding of your options and the associated costs, we have funding available to help you determine if the project is worthwhile through a feasibility study. We offer incentives of 50% of the study cost, up to a maximum of $20,000. This can be an excellent option to determine the viability of a project, including the potential energy saving and the overall project economics.

If you’re interested in saving energy and money in your agricultural operations, be sure to get in touch with us as early in your project as possible. We’ll work with you from beginning to end to implement energy efficiency solutions tailored to your long-term needs.