Whether you’re constructing a new building or replacing an existing heating and cooling system, consider a ground source heat pump — one of the most energy-efficient and environmentally-friendly electric heating and cooling systems available.

Ground source heat pumps can reduce your heating costs by up to 60% when compared to an electric furnace. Plus, we have offers to help with the cost of installing a ground source heat pump.

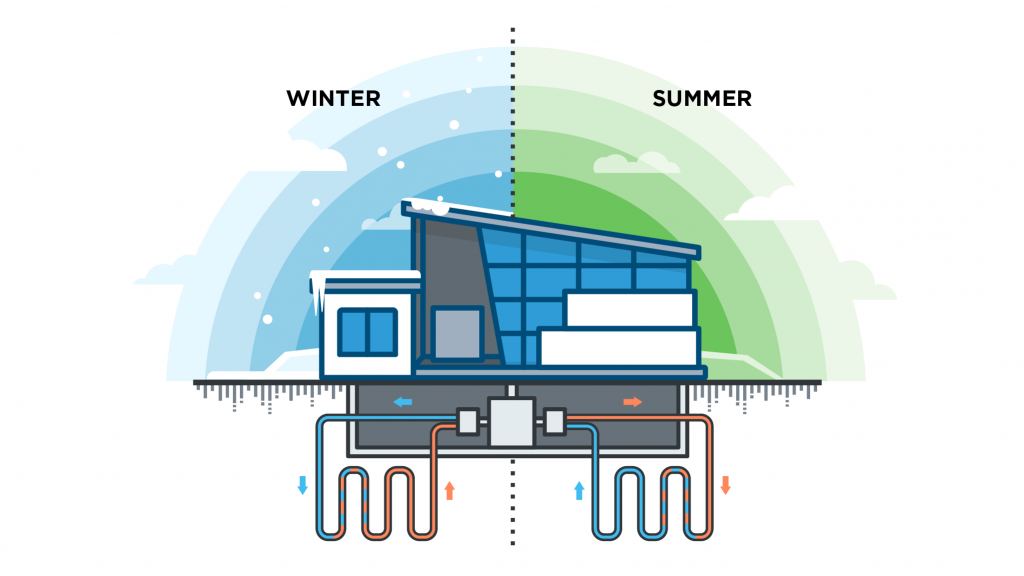

The reason ground source heat pumps (sometimes referred to as geothermal heat pumps) are so efficient is because they move existing heat into or out of the ground, instead of creating heat by burning fossil fuels or powering an electric element.

HOW A GROUND SOURCE HEAT PUMP WORKS

An electric pump circulates a heat transfer fluid through a loop of pipes which are typically buried underground. In heating mode, the fluid inside the loop absorbs heat from the earth, which stays at a stable temperature regardless of the temperature above ground (yes, even in Manitoba winters!). The heated fluid then passes through a heat exchanger into the heat pump, where the heat is extracted and delivered to either a fan coil or a radiator system in the building. This process reverses when the system operates in cooling mode and heat from the building is redistributed back into the ground.

THE IMPORTANCE OF THE GROUND LOOP

The ability of the ground loop to transfer heat from the earth to the building is what makes ground source heat pump systems so effective. The length and depth of the ground loop depends on the size of the space you’re heating and the amount of heat you need. Longer loops can draw more heat from the ground but need more space in which to be buried. Deep vertical boreholes can be drilled for loops when space is limited or to take advantage of the warmer soil temperatures available at greater depths.

When comparing quotes, pay attention to the ground loop length, depth, and spacing. Loops with tight spacing will reduce long-term heating efficiency.

WHICH GROUND LOOP CONFIGURATION BEST SUITS YOUR BUILDING?

Ground source heat pump systems use four basic ground loop configurations to turn your property into a source of energy. The best design for your needs depends on ground conditions, availability and quality of groundwater, the size of your property, and the size of the building you’re heating.

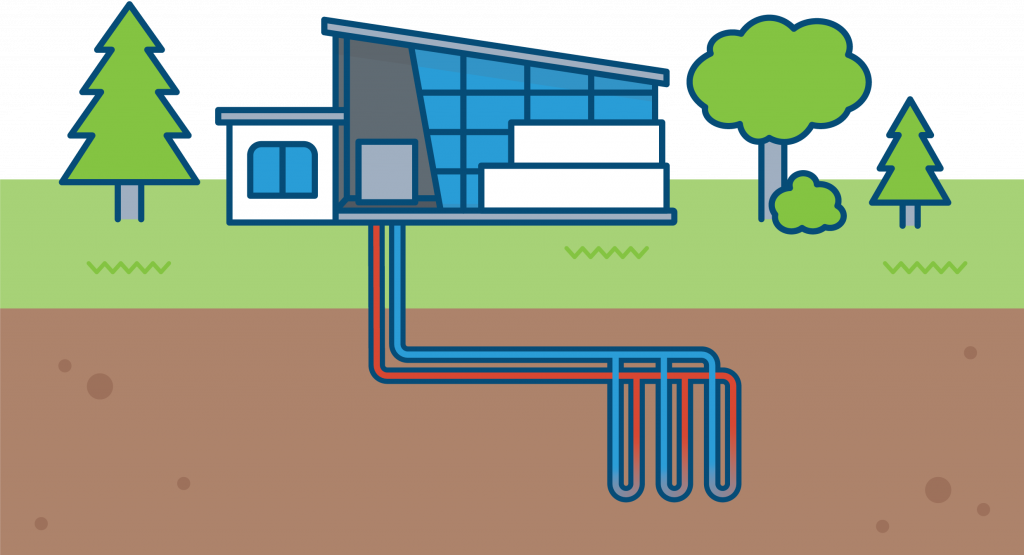

VERTICAL CLOSED LOOPS

Vertical closed loops are ideal where land is limited.

Technical details:

- Ground temperatures are more consistent at a depth of 20 feet or deeper, which means vertical loops require less piping than horizontal loops.

- In Manitoba, vertical loops are normally installed in boreholes measuring 50 to 300 feet deep and 10 to 20 feet apart.

- A pair of pipes with a U-bend assembly is inserted into each borehole.

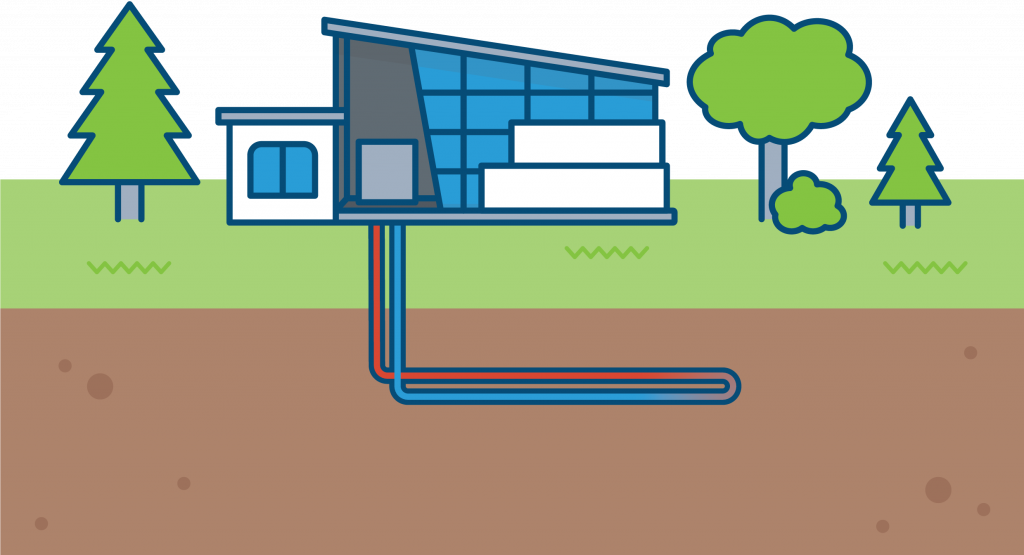

Horizontal Closed Loops

Horizontal closed loops are installed in areas where soils can be easily excavated. Because they take up more land area, they’re more common in rural areas.

Technical details:

- The pipe is buried in a long trench, usually six to 10 feet deep, in one continuous loop or a series of parallel loops.

- They can work in moist clay and/or wet sand.

- Horizontal loops aren’t recommended in dry sands and/or gravel.

- The deeper the loop is buried, the more heat there is to be harvested.

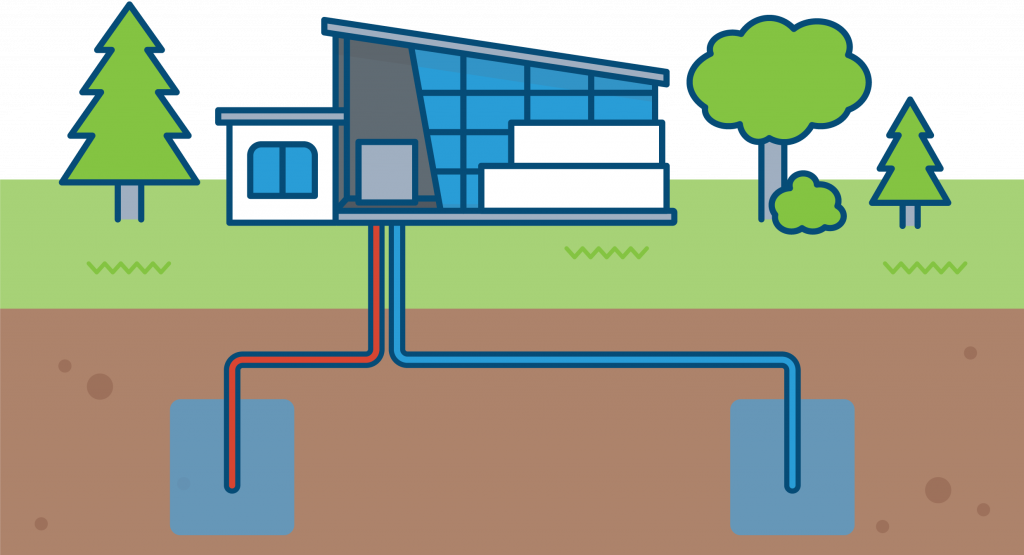

Well-to-Well or Open Loops

Well-to-well or open loop systems extract heat directly from well water. Well water is pumped from a supply well to the heat pump system and is then returned to a second well or “return well”. A Water Rights Licence must be obtained from Manitoba Water Stewardship to install this type of loop.

Technical details:

- Typically, the water entering an open loop system is approximately 6˚C warmer than a closed loop system, which can lead to improved system efficiency.

- Water sources with high levels of salt, chlorides, or other minerals aren’t recommended as they can cause premature system failure or inefficient operation. Regular cleaning and maintenance would be required.

- Installations requiring deep supply wells may need larger pumps, which would increase the initial cost of the system.

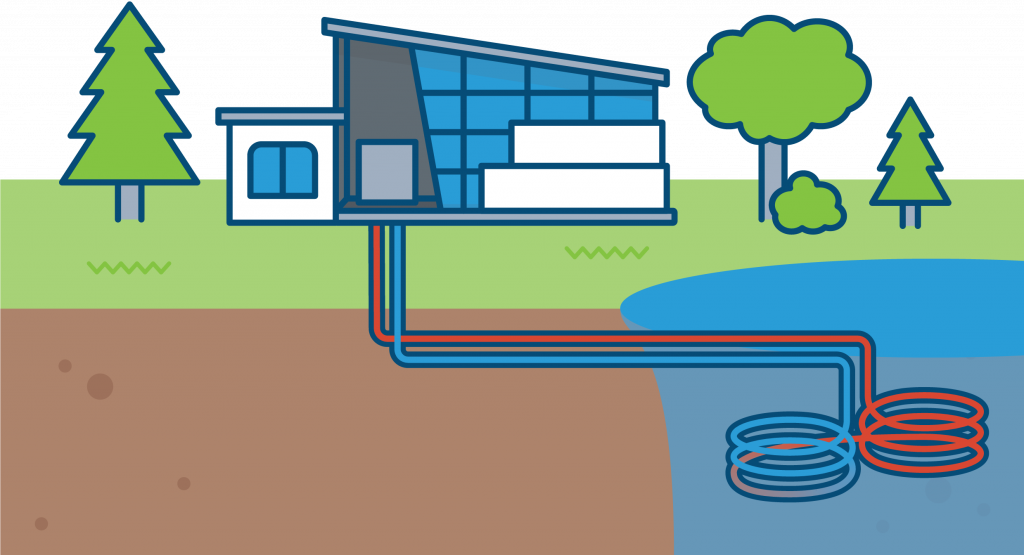

Lake or Pond Closed Loops

Lake or pond closed loops can be used if a pond or lake is nearby and the loop field can be submerged in water. Before installing this loop type, check with local authorities to ensure your plans comply with local laws and regulations.

Technical details:

- The loop field must be properly anchored to remain on the bottom of the body of water.

- It must be submerged deep enough underwater and must be protected at the shoreline to avoid being dragged by the waves.

Installing a ground source heat pump

Before you upgrade your heating system, it’s a good idea to first make your home as energy efficient as possible. Starting with building envelope upgrades, like insulation, will reduce your heating and cooling load, so your contractor will be able to properly size your heat pump system.

Once you’re ready to upgrade your heating system, we recommend getting quotes from multiple registered Efficiency Manitoba contractors and checking references before choosing a contractor. Ask each contractor about the proposed heat pump system design and how it will meet the specific heating and cooling needs of your building. If you’re participating in our Energy Efficiency Assistance Program or Métis Energy Efficiency Offers, your upgrade must be completed by a registered program contractor.

Before installing a heat pump, a heat loss/gain calculation is necessary to ensure the system is properly sized to meet your retrofit goals, such as energy use reductions or greenhouse gas emission reductions. Your contractor will let you know the most effective way to acquire this calculation. Make sure your contractor also obtains all necessary approvals, permits, and licenses.

For existing buildings, your contractor will make sure the ductwork can handle the increased airflow from the heat and the electrical panel can handle the load. This isn’t usually a concern for new buildings since the ductwork will be new and properly sized. Your contractor will also check your property to see if anything is in the way, like trees, telephone poles, or cable, electrical, or gas lines.

The groundwork has to be done in the warmer months when the ground isn’t frozen and covered in snow. In Manitoba, that’s usually from May to the end of October, depending on the year.

We also offer rebates and financial support for ground source heat pump installations! Learn more about our ground source heat pump offers and see if you qualify. Be sure to send your application for approval before purchasing your heat pump or starting any work.

LEARN MORE ABOUT OUR GROUND SOURCE HEAT PUMP OFFERS

Check out the rest of our articles in our heat pump series.